ORDERING HOTLINE : +86-532-80999083

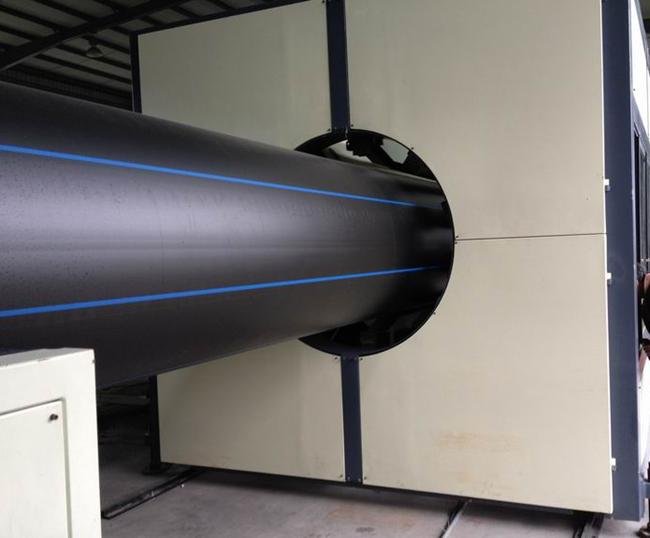

HDPE Plastic Pipes production line can make pipe excellent stiffness, flexibility, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage and so on. It has become the first choice for the city gas pipe, water supply pipe, foundation pipe, landfill collection pipe, water supply pipe, geothermal heating etc.

Structure

HDPE pipe extruding line is mainly composed of single screw extruder, die-head, vacuum calibrating stand, marking line extruder ,spray cooling tank, haul-off device, cutting device, and pneumatic discharging frame.

---Pipe diameter range: 16-63mm 75-250mm 160-315mm 200-450mm 315-630mm 500- 800mm 630-1200mm

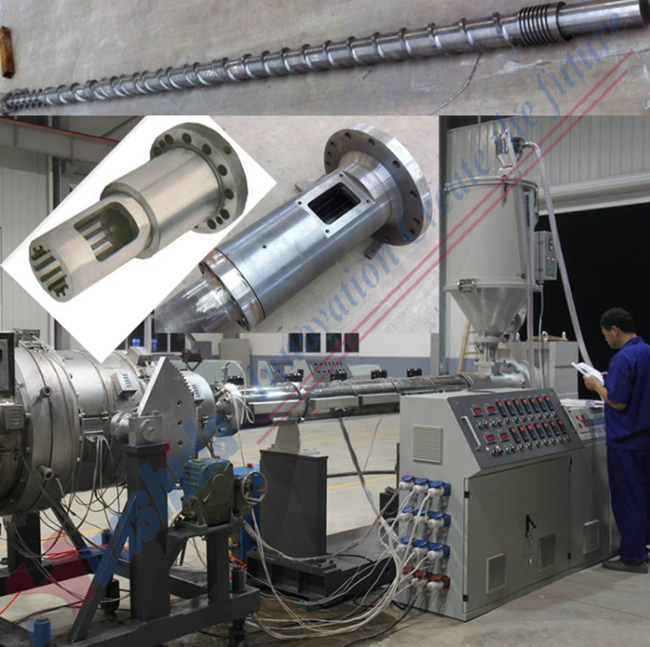

1. Single Screw Extruder

Single screw extruder is composed of AC motor, hard toothed surface ,reduction gearbox, extruding system, heating and cooling system, and electrical controlling part. AC motor connects reduction gearbox directly and make screw rotate at certain speed to adapt to extrude certain kinds of plastics. Efficient single screw extruder with water-cooling force feeding system, and barrel with grooving in the feeding zone are designed to save power of main motor; Long L/D ratio and mixing head are designed to get perfect jellification and high output.

2. Die-Head

Die-head is mainly composed of mandril, neck mold, spiral body, cover, die-head body, bolts, and heating rings. The inside surface is polished and chrome plated to ensure plastic materials flow smoothly and to ensure no rusting. The uniformity of pipe wall thickness can be adjusted by bolts. The bronze calibrating sleeve fixed in die-head is mainly used to cool down the fresh pipe and to calibrate the pipe outer diameter.

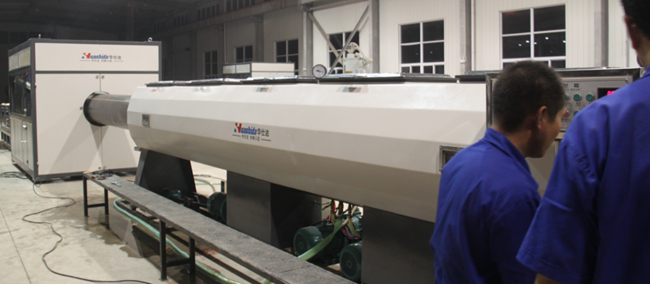

3. Vacuum calibration tank & Water spraying tank

Vacuum forming tank is mainly composed of frame, stainless steel tank, vacuum system, spray cooling system, back and forth mobile device. When it is at work, the vacuum pump exhausts the air from the sealed tank to pressurize the fresh pipe cling to calibrating copper sleeve and to realize calibrating the pipe outer diameter. Spray cooling system is used to cool down the extruded pipe by water. Spray nozzles spray cooling water from all directions on pipe surface to cool down the pipe promptly.

4. Caterpillar Haul-off Machine

Haul-off machine is mainly composed of driving device, haul-off chain caterpillar, clamping structure, adjusting system, side plate, and foundation bed. Haul-off caterpillars are AC motor driven and adopt frequency control of speed to adapt to different pipes extruding speed. It is also equipped with automatic length measuring device to achieve cutting at certain length.

5. Planetary No-Dust Cutter

It adopts blade punching principle to achieve no-dust cutting. It is mainly composed of cutting device, clamping device, structure synchronous mobile device, and frame.

Real Manufacturing Plant

| Model | Pipe range | Extruder | Installed power | Extrusion capacity | Dimension |

| SPEG-63 | 20-63mm | SJ65X30 | 120kw | 120kg/h | 36X1.8X3M |

| SPEG-250 | 90-250mm | SJ65X30 | 180kw | 220kg/h | 36X1.8X3M |

| SPEG-315 | 110-315mm | SJ90X33 | 200kw | 300klg/h | 36X1.8X3M |

| SPEG-630 | 400-630mm | SJ120X33 | 298kw | 680kg/h | 43X3X3M |

| Environmental protection, energy conservation and emission reduction!Low energy consumption, high output, low scrap rate, saving materials and time! |

| Professional team for your service, detailed pre-sales technical consultation and perfect after-sales service to solve your worries. The seller would send technician to the buyer's factory to help installing and test the new machine and train people of the buyer. |

| 12 months from date of Bill of Lading.During this period, the seller will provide free service for all problems caused by quality of equipments, however except the problems caused by the buyer because of wrong operation. |

| Pre-sales and after-sales technical support,customer hotline:0086-532-80999083 |

Global Supplier

Huashida Machinery, with over 15 years' experience, is one of the professional hdpe pu thermal insulation jacket pipe extrusion production machine line manufacturers in China. Offering the customized service, we warmly welcome you to purchase the high qualified products from our factory.

Please fill out the form below and we will reply you back as soon as possible.