ORDERING HOTLINE : +86-532-80999083

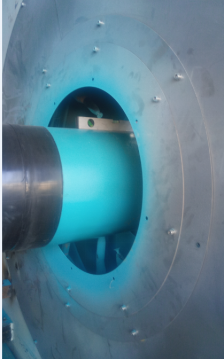

Steel Elbow 3LPE Coating Machinery is for curve steel pipe blasting&coating and PE layer wrapping machinery. It also can make 2PE/FBE coating pipe. Radius of curvature: 4-6 times D,Bend angle: 15-90 degrees.

3LPE Elbow Coating Machinery is for curve steel pipe blasting&coating and PE layer wrapping machinery. Anticorrosion form: epoxy powder + adhesive + PE tape

Material:

Steel pipe diameter: such as 426, 630, 720, 820

Radius of curvature: 4-6 times D

Bend angle: 15-90 degrees

Steel pipe wall thickness: 8 mm - 12 mm

Epoxy powder thickness: more than 170 um

Ad copolymer adhesive thickness: 170 - 250 um

PE layer thickness: 2.5 - 3.7 mm

Main machine and advantage:

Elbow conveyor line

Independent center of rotation drive

Gear ring gear drive

frequency control

The main parts adopt protective supporting wheel

The supporting wheel is equipped with slide rail, which is easy to install

Fixed angle of self-locking structure of transmission line

Height lift adjustment

Medium frequency heating

Angle handwheel adjustment

Front and rear electric adjustment

The height is adjusted through the conveyor line

Narrow thickness to avoid uneven heating in bending section

If power 350kW

Voltage and current double close regulation

Powder spraying for elbow

Annular dusting chamber

Front and rear electric adjustment of powder spraying chamber

The spray gun swings left and right

CNC adjustment of powder quantity

There are 12 powder guns

U-shaped bottom blowback recovery

Overall material 304 stainless steel

The hard negative pressure of recovery air duct does not deform

Powder injection recovery

The drawing air duct is suitable for the change of pipe diameter

Cyclone + filter cartridge dust removal standard discharge

U-shaped bottom structure + pulse back blowing to recover powder more thoroughly

304 stainless steel fluidization tank, vibrating screen powder filter, equipped with 12 venturi powder pumps

Winding machine

Automatic belt locking

One side with corrosion protection

Continuous operation of winding tape

The strip is wound tightly

High degree of automation

Automatic calculation of strip by computer

The deviation of straight pipe from the center does not affect the winding work

One step molding

Fast winding speed

Tape winding

smooth surface

The winding is even

Strong adhesion

PLC control systerm

Data collection

edit

With memory function

Automatic calculation of strip consumption

Automatic acquisition and correction of transmission speed

Please fill out the form below and we will reply you back as soon as possible.