ORDERING HOTLINE : +86-532-80999083

HDPE Jacket pipe extrusion line for pre-insulated pipe is used for extruding thin wall shell to protect the Polyurethane foaming Prefabricated Directly Buried Insulating Pipe. China manufacturer Huashida company adopts vacuum calibration method. The line runs steady. It is easy to operate by Siemens PLC. High-speed and efficient production can save costs for customers. It is an environmental protection and energy-saving production line.

HDPE Jacket pipe: dia. 48-2000mm

Carrier pipes: steel/stainless steel/plastic/copper

Insulation layer: polyurethane rigid foam Material

HDPE Jacket pipe extrusion line for pre-insulated pipe is designed by Qingdao Huashida Machinery Co., LTD. It absorbs and improves developed HDPE pipe extruding technology.

The production line is an integration design composed by extrusion, vacuum calibrating, cooling, pulling, cutting, stacker. Great performance in automatic operation, extrusion capacity, steady and service life etc. Especially compared with the line use internal pressure method, vacuum calibrating method is much better than it for stiffness, pressure resistance and surface smooth.Vacuum calibrating method pre-insulation pipe outside casing extruded line is the advanced and popular machinery in the world.

HDPE Jacket Process Flow:

Vacuum feeding PE granule-->hot air dry material-->extrusion plasticizing-->mold shaping-->Vacuum sizing-->water cooling-->Pulling out-->cutting pipe-->carrier laying-off pipe

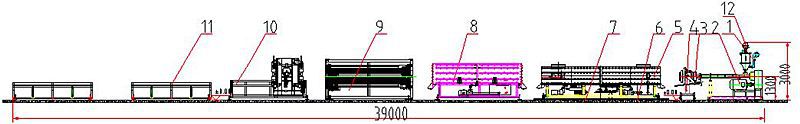

Composition of Equipments:

1.hopper dryer ⒉ Single Screw Extruder ⒊ extrusion mould die ⒋ Head bracket ⒌ Vacuum calibration device ⒏ Water cooling tank ⒐ haul-off ⒑ Planetary cutting machine 11.Pipe bracket ⒓. Loader 13. PLC

PU Foaming Pre-insulated Pipe Production process Flow:

The production process of "pipe in pipe" (PU Foaming Pre-insulated Pipe) mainly includes three steps: surface pretreatment of steel pipe, production of HDPE outer protective pipe and production of insulation layer.

The production steps of insulation layer are as follows: firstly, the steel pipe is penetrated into the high-density polyethylene outer protection pipe to form a casing structure, and the supports are evenly arranged in the annular space between the steel pipe and the high-density polyethylene outer protection pipe, and the two ends are sealed by flanges; secondly, the casing is hoisted on the foaming platform, and the polyurethane foaming material is injected into the casing by high-pressure foaming machine; finally, the polyurethane material is foamed After curing, the sealing structure at both ends is removed to complete the production process of the insulation layer.

Main machine for HDPE Jacket pipe extrusion line

Main Extruder Efficient single screw extruder with water-cooling force feeding system, and barrel with grooving in the feeding zone are designed to save power of main motor; Long L/D ratio and mixing head are designed to get perfect jellification and high output.

Die head Die-head is mainly composed of mandril, neck mold, spiral body, cover, die-head body, bolts, and heating rings. The inside surface touching with plastic materials is polished and chrome plated to ensure plastic materials flow smoothly and to ensure no rusting. The uniformity of pipe wall thickness can be adjusted by bolts.

Vacuum Calibration Tank It adopts bronze or stainless steel calibrators;The calibrating sleeve fixed in die-head is mainly used to cool down the fresh pipe and to calibrate the pipe outer diameter. High-efficiency water-spraying cooling to ensure quality of pipes.

Hauling machine High qualified rubber block is with longer life, we dont accept blocks made by recycled materials. Hauling speed is synchronized with extruder.

Chipless Planetary cutter High qualified alloy steel blade; planetary cutting to get smooth edge without plastic scrap; High precision cutting; PLC control.

Style | PE110-600 | PE655-1380 | PE960-1680 | PE1155-2000 |

Main extruder | SJ-75/33 | SJ-120/33 | SJ-150/33 | SJ-150/33 |

Pipe dia.(mm) | 110-550 | 655-1380 | 960-1680 | 1155-2000 |

Capability(kg/h) | 250-350 | 800-950 | 1200 | 1350 |

Installed power(kw) | 160 | 480 | 560 | 600 |

Length (m) | 24 | 36 | 45 | 45 |

Extrusion Line Delivery

Huashida International Trading Show

Huashida Teams

Huashida Certification

Company Profile:

Business Type: Manufacturer/Factory & Trading Company

Main Products: Pre-insulation pipe jacket extrusion line, 3LPE coating pipe production line, HDPE sheet extrusion line, heat shrink sleeve, HDPE electro-fusion tape

Number of Employees: 80-100

Year of Establishment: 2003

Management System Certification: ISO 9001, ISO45001 ,ISO9001

Location: Qingdao, China (Mainland)

| Environmental protection, energy conservation and emission reduction!Low energy consumption, high output, low scrap rate, saving materials and time! |

| Professional team for your service, detailed pre-sales technical consultation and perfect after-sales service to solve your worries. The seller would send technician to the buyer's factory to help installing and test the new machine and train people of the buyer. |

| 12 months from date of Bill of Lading.During this period, the seller will provide free service for all problems caused by quality of equipments, however except the problems caused by the buyer because of wrong operation. |

| Pre-sales and after-sales technical support,customer hotline:0086-532-80999083 |

Global Supplier Huashida Machinery, with over 15 years' experience, is one of the professional hdpe pu thermal insulation jacket pipe extrusion production machine line manufacturers in China. Offering the customized service, we warmly welcome you to purchase the high qualified products from our factory.

Huashida Machinery, with over 15 years' experience, is one of the professional hdpe pu thermal insulation jacket pipe extrusion production machine line manufacturers in China. Offering the customized service, we warmly welcome you to purchase the high qualified products from our factory.

Please fill out the form below and we will reply you back as soon as possible.