Steel Pipeline (3PE) heat Shrink sleeve Repair Operating Instructions

1. Steel Pipe Cleaning: After cleaning the weld seam and burrs, welding slag, oil and dirt near it, rust removal by sand blasting or electric tools should be adopted. The surface of the steel pipe after rust removal should reach GB8923 Sa2.5 and Sa3.0 levels, respectively.

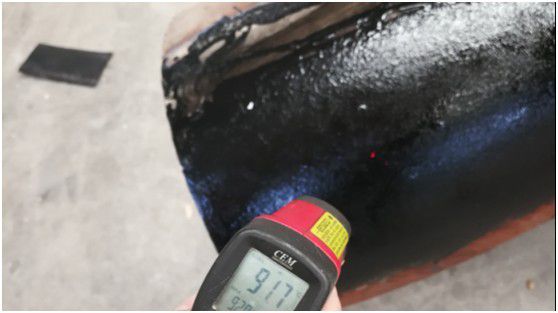

2. Preheating of steel pipes: Preheating the filling and anti-corrosion coating surfaces of steel pipes to 60-90 C.

3. Paint primer: Mix two-component epoxy coatings and stir them evenly for 2-3 minutes, then use special paint brush to brush the coatings evenly on the steel pipe joint.

4. Installation of heat-shrinkable tape: heat the hot melt adhesive at one end of the heat-shrinkable tape overlap connection to soften it, place it in the center of the weld about one minute, press it flat with a small roll; then heat and soften the hot melt adhesive at the other end of the heat-shrinkable tape and overlap it on the heat-shrinkable tape according to the overlap connection, and press it flat with a small roll at the same time.

5. install fixing sheet: heat the wordless side of fixing sheet to soften and cover the joint of heat shrinkage belt, and compact the fixing sheet with small rollers or hand (wearing gloves).

6. Heating shrinkage: Heating shrinkage should be uniformly heated from the middle position along the circumferential direction to make the central part shrink first. The heat shrinkage band is then contracted by uniform heating to both sides.

we can supply 3PE heat shrink sleeve. Email: hsdc@qdhsd.com, whatsapp/wechat:008613963975523,www.hsdanticorrosion.com