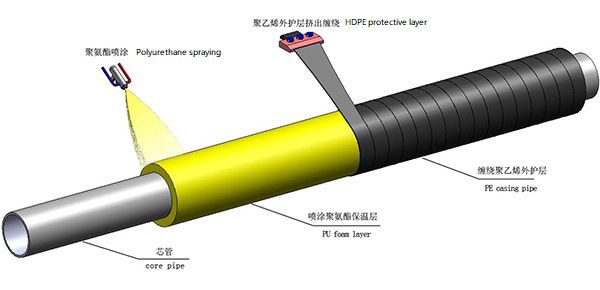

1. Pipe structure;

3-Layer Polyethylene (3LPE) is a multilayer coating composed of three functional components: A high performance Fusion Bonded Epoxy (FBE) primer, followed by a copolymer adhesive and an outer layer of polyethylene which provides tough, durable protection. 3LPE systems provide excellent pipeline protection for small and large diameter pipelines operating at up to moderately high temperatures.

2. Long term corrosion protection

The FBE component provides excellent adhesion to steel, providing superior long-term corrosion resistance and protection of pipelines operating at moderate temperatures.

If required, Low Application Temperature(LAT) FBE can be selected as the primer to ensure low preheating conditions and long term integrity of high strength steels (X80 or higher)

In addition, 3LPE systems offer excellent resistance to cathodic disbondment, reducing lifecycle costs of cathodic protection

3. Engineered solutions

Advanced Manufacturing techniques allow for a customized 3LPE system to your specific project.

4. Very good mechanical protection

The tough outer PE layer protects pipelines during transportation and installation thereby reducing costly repairs while also providing added in-ground protection against shear forces, chemicals and abrasive soil conditions

By increasing the thickness of the PE outer layer, the 3LPE system can provide a high level of mechanical protection across a variety of difficult environments without requiring the use of costly backfill

Qingdao Huashida committed itself to innovation and invention. Through the past 20 years, Huashida has accumulated mature experience in addition to state of the art technology. Welcome to hsdb@qdhsd.com or WhatsApp +86 13953294241 for more information and latest quotation on the line.

Revi: Huang Baodong's PERT Technology Application Report at the Uzbekistan National Design Institute